Quartz Slab Plant Design

To correctly design a quartz slab plant, various commercial and technical variables need to be defined. Customer and supplier must carry out a thorough joint analysis during the configuration phase in order to optimize the process and adapt the layout and the equipment to the customer's specific requirements. Some of the key questions to answer:

- What is the yearly production goal (m²/y)?

- Which design are you manufacturing (Super White, Single color, Veins, Multicolors, Special designs)?

- What is the expected average lot size (slabs/order)?

- Which level of automation is required (Fully automatic, Semiautomatic, Manual)?

- This is a very important question because VEEGOO provides automatic production lines only.

- What are the desired levels of quality and repeatability?

- Will the line be installed in a new building? If not, could the existing building impose limitations on design and layout?

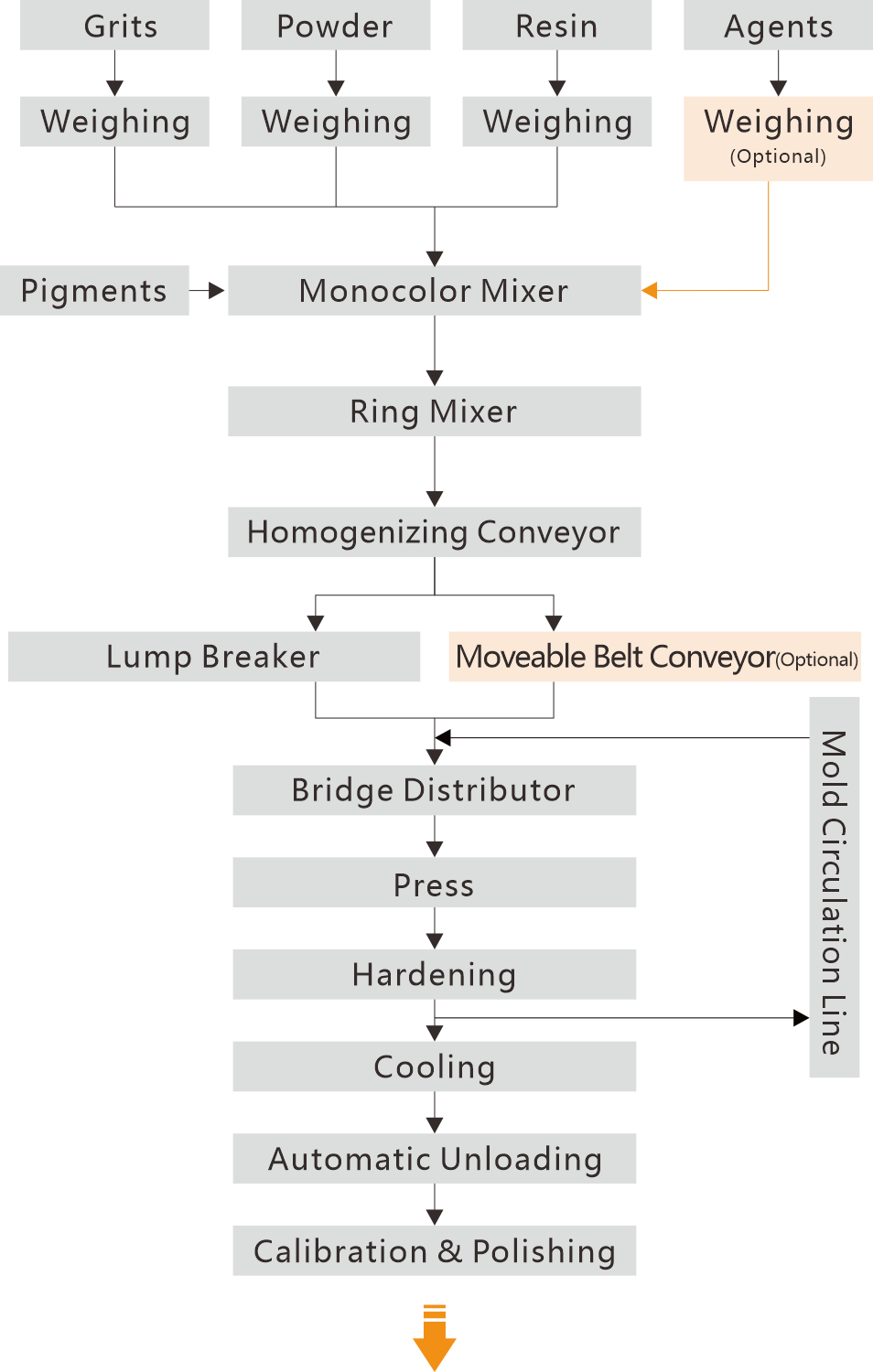

Flowchart of Quartz Slab Plant

This production line can produce standard color schemes including solid colors and multi-tone blends, fulfilling the fundamental production requirements of clients. By optionally integrating a Matrix (matrix pigment spraying) and StatuTikar (CNC Veining robot), it can be upgraded to create premium finishes such as elongated vein patterns.

"2+1" Dual System

If you want to produce normal design slabs, and at the same time, produce special design slabs, we suggest you to choose this “2+1” configuration.

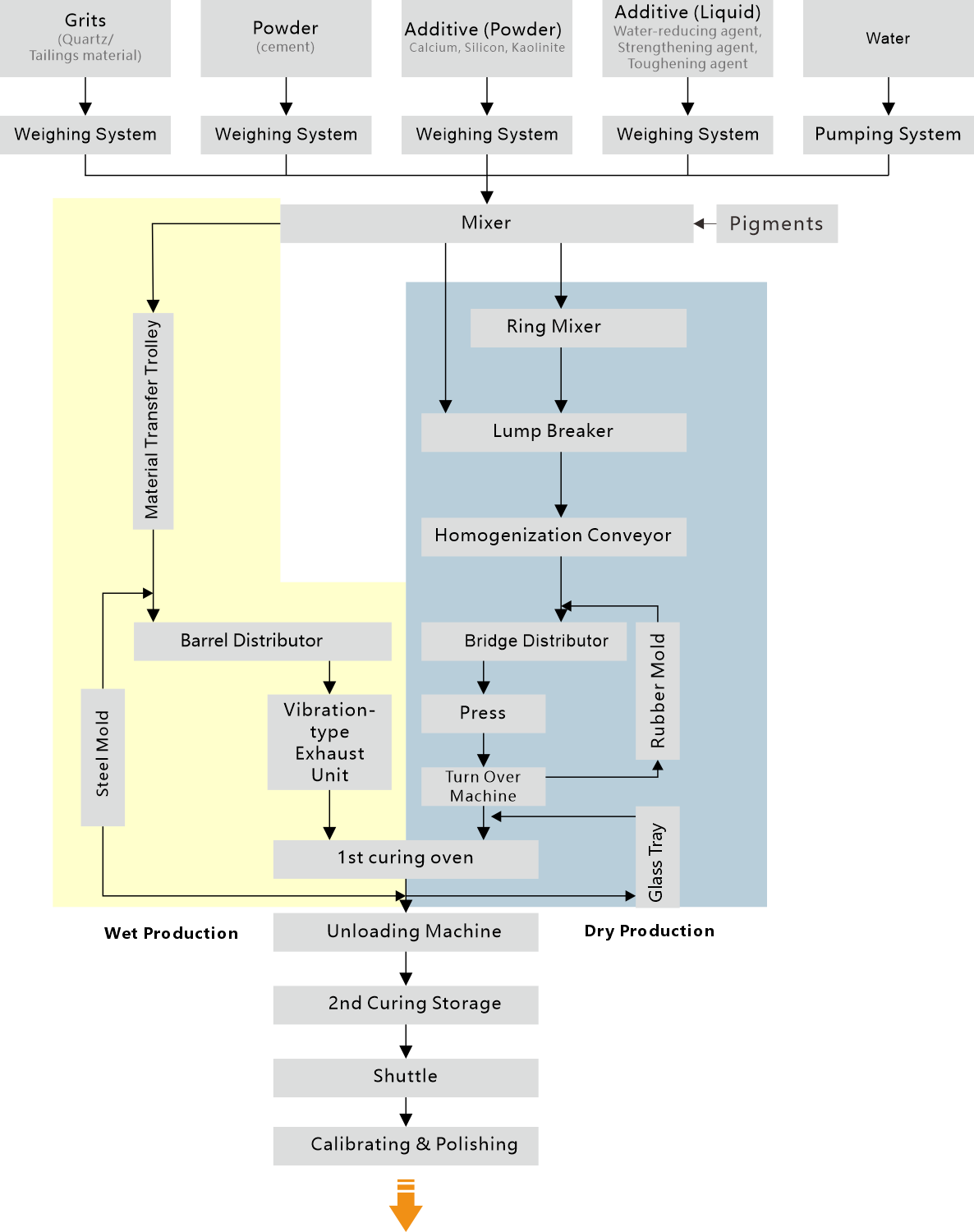

Cement Based Slab Production Flowchart

From the beginning to the end, it is whole production line mode with high degree of automation and intelligence. Few labor only controls the equipment operation. The labor only monitors equipment, and the materials are not landing, so it is easy to realize the system management.

Quartz Plants Classes

Based on our experience, the Pareto principle, or the 80/20 Rule, applies when designing a engineered stone. Only 20% of the plant´s design needs to be customized, and 80% consists of fine tuning the following three classes.

Buildings and Layouts

"New or existing?" That is the question. New buildings offer the opportunity to free the imagination in search of the best possible solution without any constraints. In such cases, it is possible to adopt left-to-right or right-to-left material flow, together with various layout configurations ("I", Parallel"I", "L", "C", etc.) to optimize operations and minimize floor space requirements.

Existing buildings on the other hand, can occasionally impose limitations on an optimal design.

In such cases, the net height under the crane hook and the possibility of digging specific areas of the building are key factors.

In a nutshell, an optimal design is one that optimizes material flow, provides special by-passes for processing specific designs, and minimizes floor space requirements while preserving ergonomics, safety, and efficiency.

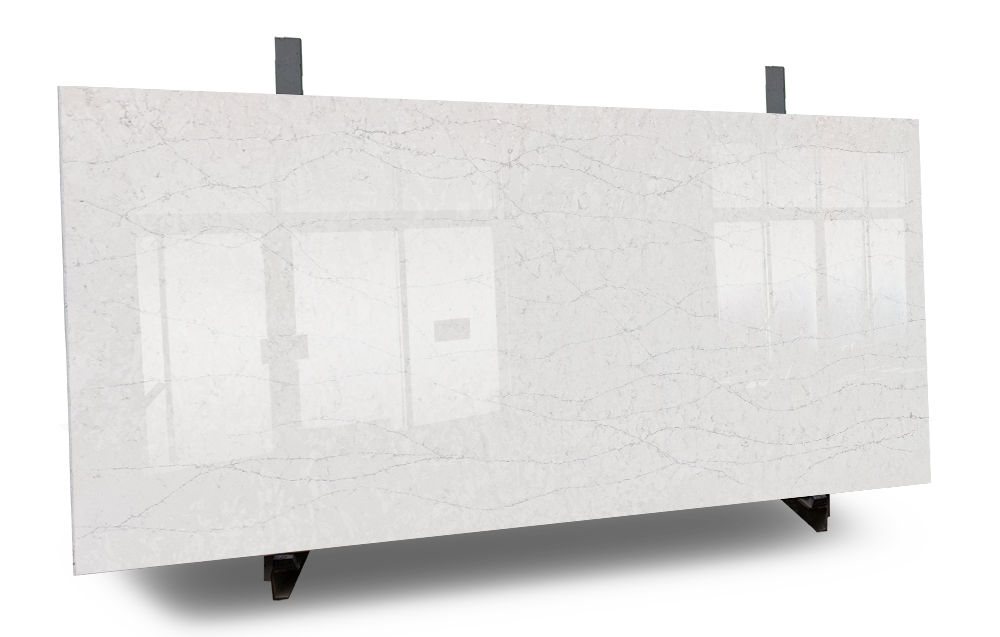

What can you make with a VEEGOO line?

Virtually anything. It is possible to produce any slab design of the highest possible quality, excellent reproducibility,

extreme reliability, all at very low production costs, which serve to ensure a good return on investment.

Control

Quartz lines are a complex assembly of customary and well-established technologies. By using proper designs, the correct choice of materials, generous thickness levels, adequate components, professional planning, mechanization, and proper assembly and installation processes, these plants are highly reliable and assure a prolonged Mean Time Between Failures (MTBF). At VEEGOO, we use Chinese components only if they meet our quality standards. Otherwise, we go for imported, high-class components from providers in Europe, Japan, Taiwan, or Korea.